Everyone loves the turning of the seasons, what with leaves changing, snow falling, pools opening, and the like. But Mother Nature has little concern for the comfort of humans, so fluctuating temperatures bring the need for residential heating and cooling.

In condominiums, cooperatives, and homeowners’ associations, residential heating and cooling (HVAC for short) can be major, both in terms of financial cost and energy expenditure. To keep those under control, it would behoove any association board to stay on top of the latest trends and innovations in HVAC, and make sure their own equipment and systems are up-to-date and well-maintained.

All the Small Things

Starting at a micro level, there are things that every unit owner or shareholder can do within their individual domiciles in order to conserve energy and help cut costs, both for themselves, and community-wide.

“People will ask about installing solar panels or wind towers and all of that fancy stuff, but the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) guidelines recommend that one not touch any renewable energy source until they fix simple things within their buildings via an energy audit,” says Brendan Yadav, principal at Yadav Solutions, Inc., in New York City, adding that if an association doesn’t take care of local, more minor inefficiencies before attempting an HVAC overhaul, they won’t get the full benefits of that upgrade.

For example, in units with radiators, Yadav recommends reflective jackets that help contain heat that may get lost between the radiator and a window. “And speaking of windows, make sure that those are caulked and sealed nicely, and that the operable parts are operable, while the inoperable parts are inoperable,” Yadav says. “Just make sure that they’re adequately maintained.” He also recommends holding a lighter to the base of a closed window to ensure that no excess air is getting in. If the flame wavers, chances are you’ve got a draft – and in addition to being chilly, you’re also paying for wasted heat.

Michael Vinick, president of Duct & Vent Cleaning of America, Inc., headquartered in Springfield, Massachusetts, also suggests that individual residents invest in air duct cleaning to ensure that their investment is protected. Clogged, congested vents move less air, and require more energy to move the air that does get carried from furnace to individual units, so keeping ductwork clean essentially opens up the pathways, making the whole system more efficient.“This creates a more optimal living environment,” he notes. “Also, make sure that your HVAC contractor inspects your air-handling unit on an annual basis.”

Something as simple as opening curtains to reduce the need for artificial lighting, or making sure that appliances and water are turned all the way off when not in use can make an impact as well, according to Ricardo Martinez, a staff engineer with m2e Consulting Engineers in Miami. “Of significant note are what we call ‘energy vampires,’ which are appliances and devices that have a standby mode that continues to use electricity, only at lower levels,” Martinez explains. “Typical devices include cable/satellite boxes, computers, printers, microwaves and cell phone chargers. Residents can connect these devices and appliances to power strips to easily and quickly turn them off. Residents can also use outlet timers to turn devices on for a specific amount of time.”

Going Big

There is no one way to upgrade or modify a building’s HVAC systems. A property’s size, infrastructure and layout all must be considered when contemplating a project to curb energy usage or save precious association funds. What’s more, the same smaller problems – air leakage, dirty filters, etc. – that can afflict an individual unit can affect the common areas of a building.

“Depending on the age of a building and its design, there are several reasons why an occupant may see increased costs associated with HVAC,” says Vinick. “The building may not be ‘tight’ – i.e., air leakage, or drafts, may be prevalent. Older air-handing units are not energy efficient. There have been huge advances in technology making furnace ‘change-outs,’ or upgrades, worthy of consideration. The payback is reasonably quick.”

Martinez asserts that the key technology for reducing energy usage is a highly functional, flexible and integrative building management system (BMS). “BMS allows for directly monitoring data usage,” he says. “You cannot fix an energy usage problem if you don’t have the information or the data to see where those problems are located. Having a BMS station also allows for easy scheduling and programming of devices to account for situations such as holidays, events, storms etc., that can optimize the usage of your HVAC system.

“Many BMS vendors and installers are also offering demand flow optimization,” he continues. “This approach uses sensors and programming to optimize the chilled water and variable air volume demands in a building, to ensure occupant comfort while minimizing the use of building resources.”

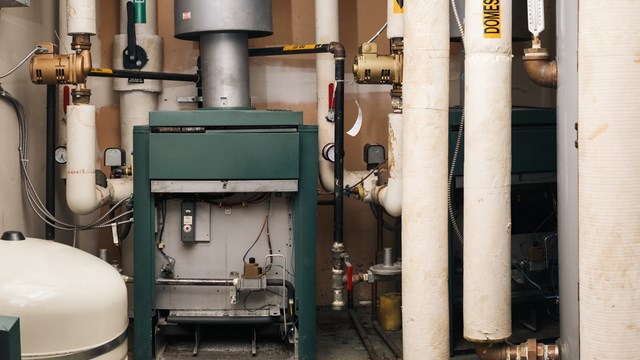

Yadav suggests that associations look into variable refrigerant flow systems. “These offer a more compact, economic method of pumping heating and cooling throughout the building,” he explains. “A boiler is a heavy medium and utilizes a lot of energy circulating steam or water throughout the property. But nowadays you have refrigerant flow systems, which are packaged units that are usually as small as a garbage can, and never bigger than a dumpster. With the smaller units, you can stick them outside on a banister, porch, roof, balcony, etc., and get individualized cooling on an entire floor of up to 15,000-20,000 square feet.”

And he similarly advocates for packaged modular boiler systems. While a large boiler needs to meet a certain energy threshold to be at all effective, smaller modulated units can offer heat more to the operator’s discretion, which conserves energy. “We’ve been having warmer winters and springs, so are you always going to need that big boiler to get all the way up to a designated pressure and temperature? Or can you just replace the large boiler with five smaller ones that use 1/5 of the power?” In the latter scenario, should the weather skew warmer, you only need to utilize as many boilers as is necessary for comfort.

On the flip-side, there are products that the pros say boards would be advised to steer clear of. “Two of these in particular are ‘smart vents’ and ‘condensing unit misters,’” warns Martinez. “Smart vents purport to save residents energy by closing the vents to unused rooms. However, by closing vents, these devices can potentially damage the blower and cause the coils to freeze. And condensing unit misters claim to save energy by essentially converting the condensing units into cooling towers. However, since most condensing units are designed to be air-cooled rather than water-cooled, they are more likely to make your system less efficient, and cause damage by corroding the fins of your condenser thus reducing its lifespan.”

A board would always best be served to consult with an engineering professional before taking on a major HVAC project.

Steady Maintaining

Of course, no upgrade will prove effective if an association isn’t subjecting its HVAC systems to routine maintenance.

“Too many common areas and individual units only get serviced when something isn’t working,” says Fritz Kreiss, president of Alternative Utility Services, Inc., an energy use consulting company with offices in Wisconsin, Illinois, and New Jersey. “An ongoing service plan with preventive maintenance can more than pay for itself through energy savings, as well as the extension of equipment life. Many utilities also offer rebates on recommissioning equipment, which brings it back to original equipment specifics. As buildings get older, it is also important to look at the expected life of equipment. Many chillers and boilers are kept beyond the expected life, at a high cost of energy and maintenance compared to a new system. When a new system is installed, care should be taken to isolate the new boiler or hot water heater from the distribution piping. Over time, old pipes can accumulate a lot of calcium, which can plug up – and eventually burn out – the new high-efficiency boilers’ heat exchangers. The old boilers could handle this because of their inefficient design, while the new boilers have tolerances that would get gummed up. An old chiller might be using 1.2kW per ton of electricity, while a new centrifugal chiller might use 50 percent less.”

Martinez concurs. “Having a preventative or predictive maintenance schedule can reduce energy consumption anywhere from five to 20 percent,” he says. “Properly maintaining your equipment keeps the equipment running as efficiently as possible, and reduces the performance loss throughout the system. With multiple pieces of equipment throughout the system, performance loss in each individual piece can cascade into a large inefficient system, which makes for an energy-wasting and costly system.”

Thus a board should take heed to ensure that it’s done everything it can to optimize its current system before upgrading to something new. Fixable problems within an existing system may well replicate themselves in another, more expensive installation.

Mike Odenthal is a staff writer/reporter for The Cooperator.

Leave a Comment