Cleaner skies, healthier lives and a shinier Big Apple are some of what the much-talked-about changeover from No. 6 and No. 4 fuel oil is intended to accomplish.

Under New York City's “Clean Heat” mandate (part of former Mayor Michael R. Bloomberg’s PlaNYC environmental makeover of the city), about 10,000 residential buildings have been phasing out the use of No. 6 and No. 4 heating oils in their boilers. Permits for No. 6 oil (the more polluting of the two) began expiring in 2012 while new permits for use of No. 4 already were being denied in the summer of 2013. As of July 1, 2012, buildings using No. 6 oil had to convert to using No. 4 oil, which contains less sulfur, or switch to a cleaner burning fuel like No. 2 oil or steam, before their boiler’s 3-year certificate of operation expires. All new installations must utilize one of the cleanest fuels, which may include natural gas, ultra-low sulfur No. 2 oil, biodiesel or steam, according to www.NYCcleanheat.org.

What's in a Number?

The three types of heating oils are differentiated by the extent to which each has been refined. No. 6 is the least refined; therefore it's the lowest-quality and contains the most toxins of the three. It’s thick, sludgy and must be preheated in order to be used in a boiler. This means that if a boiler is using No. 6 oil, it must also have an electric heater constantly running to keep the oil usable—which is of course not the most efficient use of energy. At the mid-range is No. 4 oil, which is a blend of No. 2 and No. 6, and is somewhat cleaner and more efficient. Of the three types, No. 2 oil is the most refined and cleanest burning. It’s closest in quality to diesel fuel, but it’s also the most expensive.

The No. 4 andNo. 6 phase-out was mainly intended to reduce pollution-related adverse health effects (and therefore save lives in the long term), and also to make New York City a cleaner, more livable metropolis. But as with any major transition—especially one in a huge city with hundreds of thousands of buildings—the switch to cleaner burning fuel oils hasn’t been totally wrinkle-free. Part of the difficulty is due to the price of conversion to a natural-gas heating system, which can run upwards of $100,000, depending on a building's age and size.

The process a co-op or condo building must go through to upgrade or retrofit their boiler to be compliant with the new policy, and problems some buildings have run into while working toward compliance, are worth understanding. Boards and managers who want to best serve their communities while successfully navigating the transition should make it a point to be as knowledgeable as they can about the switch.

Like so many aspects of building maintenance, making the heating oil transition process as smooth as possible will save everyone cash in the long term; the savings will come through lower fuel costs due to upgraded systems, and lower heating system maintenance costs. But perhaps the greatest benefit—of not having to keep your apartment windows closed to avoid to ugly and noxious black soot pouring from a neighbor’s chimney—well, that just might be priceless.

Life and Breath

The American Lung Association was started in the early 20th century to fight tuberculosis, and once had the tagline: “It’s a matter of life and breath.” More than a century later, the line dovetails perfectly with the push to achieve cleaner air in New York City, a chief component of which is PlaNYC's Clean Heat effort, which city leaders believe will save thousands of lives over the next few decades.

According to the PlaNYC website, air pollution is one of the greatest environmental threats to New York City, contributing to six percent of the deaths in the city each year. Fine particulate matter in Gotham's air, which is tracked by the U.S. Environmental Protection Agency (EPA), annually causes more than 3,000 deaths, 2,000 hospital admissions and 6,000 emergency department visits for asthma in children and adults.

Based on those figures, it might seem like nearly every building in the city must be belching smoke to produce such an unnatural, deathly haze. But actually, just 1 percent of all the buildings in the city produce a whopping 86 percent of the total soot pollution emitted from buildings. That’s more pollution than emissions from all the cars and trucks in New York City combined—and it's the direct result of the cruder, more sulfurous No. 4 and No. 6 oils. As of mid-2014, No. 6 oil should be fully phased out of use, according to PlaNYC’s website. By 2030, or when a building’s burner is replaced (whichever is sooner), all buildings with boilers that are burning dirtier oil must convert to one of the cleaner burning fuels.

Making the Switch

Changing from No. 6 oil to No. 2 oil or another cleaner burning system should be undertaken with professional help. An engineer who understands the oil changeover protocol, an energy efficiency expert, or a qualified boiler maintenance company are some of the suitable professionals to contact for such a consultation. Board members and residents who want to learn more about the changeover can do so by attending seminars on the topic, but whether or not they have such training, board members should get an expert to undertake a feasibility study before any work is done on changing the heating system.

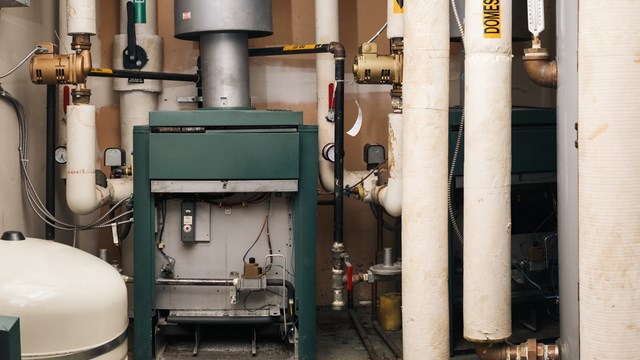

A feasibility study examines the limitations and usable life of the heating system. It’s a preliminary inspection of the system and its layout to help determine if changes to the boiler or to the boiler room (such as removal of walls) will be needed. The study also will determine if the existing system can burn No. 2 oil and if so, if that is the best course or if a changeover to natural gas is wiser.

When a board chooses its boiler replacement/alteration course, the engineer should create specifications for the work and put out a Request for Proposals (RFP) for the project. After getting RFPs from contractors interested in the work, the contractors should be vetted, and board members can choose the best contractor for the job, based partly on the engineer’s recommendation, the price of the contractor’s bid, and the company’s track record.

Particular buildings, such as some in Manhattan, will find it more difficult (maybe even impossible) to convert to natural gas. Pockets of the city still lack natural gas line service and some have the lines but they are inadequate to provide upgraded service. That being said, those areas are shrinking because consumers see the potential for huge savings and are demanding natural gas.

The actual mechanics of switching oil types or of switching from an oil burning system to natural gas service depends partly upon the state of a building’s boiler. Whether or not the boiler can be adapted to run on the cleaner oil or natural gas must be considered, and building management must weigh if it makes financial sense to do such a conversion. A comparison should be done of the cost for a retrofit versus the cost of a replacement of the entire boiler. The boiler may be too old for it be economically updated, which would make replacement the only real option.

Oil or Natural Gas?

In parts of the city where the switch from heating oil to natural gas service is available, more customers are making the change. To the management of many buildings, that changeover is simply more practical, since the price of natural gas is more economical compared to using heating oil for a building’s boiler. The disparity in cost for heating oil—an internationally traded fossil fuel heavily dependent upon price challenges and changes worldwide—and natural gas, a fuel in great supply in North America and less susceptible to market fluctuations, should continue for many years, experts say.

Roughly speaking, the savings in energy spending available by switching from oil to natural gas is about 50 percent, says Joe McGowan, manager of gas customer solutions for Con Edison. There are a couple of ways customers can realize savings by switching to gas, and those are determined by the sort of delivery system they choose.

Some residential buildings elect to have boilers with the capability of using either gas or heating oil—a dual fuel heating system. Simply stated, a dual fuel system is combining the installation of a gas or oil furnace with a heat pump. A dual-fuel unit usually costs about $600 to $1,000 more than conventional heating and cooling systems because you’re getting essentially two systems in one. But the amount saved in the next three years from lower heating costs should make up the difference in cost.

If you and your neighbors are confident in your gas supplier—or your boiler isn't capable of burning both—you could choose to get a so-called “firm rate” from Con Edison (or another supplier, which likely has a similar program). The method enables the utility to provide some initial improvements to the system for free, as well as a fixed per-therm rate, McGowan says.

Another way to save is to subscribe to an “interruptible” rate, which is a lower rate the gas company provides in exchange for being able to interrupt your service if needed. This method works well for a building that has a switching capability on the boiler, enabling the equipment to be switched from using gas to burning heating oil or another fuel. But for some customers in Manhattan, it could make more sense to become a steam customer, rather than switching to gas.

Co-generation in buildings also is happening more frequently, energy experts say. “It’s happening; we’re seeing more and more of it. It’s probably the next thing that will be coming,” McGowan says.

McGowan adds that in addition to the added convenience of not requiring deliveries, as is needed for heating oil-based systems, natural gas utilities provide a continuous supply of the fuel to their patrons. While it might sound simple, there’s a lot less hassle when you remove the need to have physical deliveries of the fuel. To put that in perspective, consider that a 100-unit apartment building will use about 70,000 gallons of heating oil each year.

Changing over to a natural gas system shouldn’t be taken lightly, since it’ll be a system the building is stuck with for many years. Potential customers should do their homework on the subject, and then approach your fuel provider with more questions. “But first, assess your internal conversion costs,” McGowan says.

According to Mark De Yoanna, a customer and business strategist for Brooklyn-based energy firm National Grid, “When the Clean Heat law was passed in 2011, it aligned with moving our customers to natural gas. It gave customers a real urgency for the conversion,” he says. De Yoanna admits there are some infrastructure gaps, including spots in Manhattan, where new gas service is not yet available, but those gaps are being filled. “Our goal is to get customers connected at little or no cost,” he says.

Perhaps one of the biggest obstacles for some buildings in making the conversion to gas is the cost. Such a change requires infrastructure improvements including sometimes a new boiler, and also a chimney liner replacement. Depending upon the building’s chimney, that price tag could range from $50,000 to $150,000.

“It all adds up. But the payback is really there,” says Mike Ruiz, director of community and customer management/New York, for National Grid. “Over the long haul, it’s the better investment for customers. We’ve seen the U.S. go from being a huge importer of natural gas to a potential exporter of natural gas.”

Jonathan Barnes is a freelance writer who regularly contributes to The Cooperator and other publications.

Leave a Comment