Like many questions, the answer is "it depends." Many people think about a 20- or 30-year-old boiler the same way they think about a 10- or 15-year-old car: "It might need to be replaced soon, so I won't spend much money on it. I'll just wait and see what happens." When a car makes it several more years, people start to think, "If it lasted this long, there is no telling how long I can keep it, so I'm going to take good care of it." The same thing tends to happen with boilers if they make it to 40 or 50. The trick is knowing whether or not the boiler is likely to keep working for years and years.

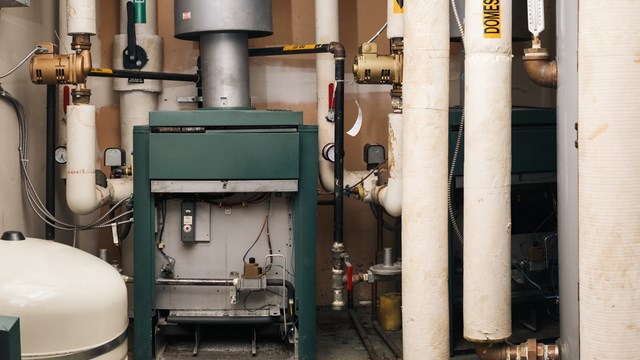

There are several factors to consider when deciding whether to keep an existing boiler or install a new one, but the main factor is the condition of the metal the boiler is made of. Others include the condition of the doors, brickwork, burner and controls, and the suitability of the existing equipment to the application. If the boiler is the wrong size it might be wise to replace it regardless of its condition.

A visual inspection of the metal inside of the boiler is the most reliable way to assess the condition of a boiler, and should be done whenever practical. Steel boilers over 100 horsepower, which typically might be found in a multifamily building, are equipped with manholes that can be removed so the inside can be inspected visually. However, cast-iron boilers and many steel boilers do not have provisions for inspecting the inside. Shutting a boiler down and draining it to open it up is not an every-day event, therefore other methods must be used. If local codes or insurance regulations require annual internal inspections, checking the condition of the boiler once a year usually is a good measure.

As mentioned, the condition of the metal the boiler is made of is a primary consideration for boiler repair or replacement. How does metal begin to deteriorate in the first place?

Some boilers are used in applications such as hot water heating systems that, theoretically, are closed loops with no water lost from the system. Other boilers never heat the same water twice. For example, a desalination boiler on a submarine boils seawater to separate the water from the salt so the resulting steam can be condensed into drinking water. The salt stays behind in the boiler, which is frequently cleaned by blowing it down with pressurized water or steam, and mechanical cleaning. Most boilers fall somewhere between these two extremes, using a mix of new and recirculated water.

If the system the boiler is connected to is supposed to be a closed loop, or a mostly closed loop, but has leaks, then liquid water or steam that leaks out is replaced by new water containing new oxygen and new minerals. If the boiler is connected to a steam-heating system, the water absorbs oxygen from the air that the steam pushes out of the radiators and piping each time the system fills with steam. If the boiler is not protected somehow, the oxygen and minerals in the water eventually will destroy the boiler. This is probably the most common cause of deterioration in apartment house boilers.

The oxygen in the water and the metal the boiler is made of combine to form rust at the inside surface where the water and the metal touch, regardless of whether the boiler is made of cast iron or steel. This degradation continues until the metal gets so thin it fails and the boiler leaks water or steam.

Obviously, an unprotected boiler that has had a large quantity of new water fed into it will be in worse condition than if it were protected or had little or no new water fed into it. There are various strategies available to protect boilers against being damaged by oxygen and minerals in water. These include chemical treatments, anodes, and feedwater heaters.

Chemical treatments are commonly used to reduce the problems associated with oxygen and minerals in boiler water.

Two typical treatments consist of:

"¢ Using substances intended to keep minerals dissolved in the water so they leave the boiler through leaks or when the boiler is drained, instead of remaining behind and building up scale.

"¢ Using chemicals intended to react with oxygen in feedwater to prevent the oxygen from reacting with the metal the boiler is made of.

Chemicals called chromates are very effective and were used for years until they were banned for causing health problems. Local suppliers can provide less dangerous chemicals optimized for use with the water in a particular area. Whatever chemicals are used will be lost through any leaks in a supposedly closed-loop system, so colored dyes usually are added to the chemicals to help detect their loss. We presume that if dye is still visible in the boiler water the chemicals did not leak out, and if the dye is gone, so are the chemicals.

Sacrificial anodes are available for boilers. These are pieces of metal that oxidize more easily than the boiler, thereby protecting it. Storage tank type water heaters commonly used in houses typically contain anodes, and water heaters with longer warranties typically have either a second or a larger anode. Periodic replacement of the anode(s) can extend the life of a water heater or a boiler, although new boilers often are not equipped with anodes.

Feedwater heaters, which protect a boiler by heating feedwater to drive off oxygen dissolved in the feedwater, are also available. Feed-water heaters are used on large boilers that consume large quantities of feedwater, such as steam boilers found in large industrial applications and power-generating stations. Feedwater heaters generally are not used with heating boilers found in apartment complexes or single-family houses.

Reducing the amount of new water entering a boiler protects a boiler better than any chemicals or anodes can. If no new water enters a boiler, and the water does not absorb oxygen from exposure to air, there is very little oxygen available to rust the boiler and no source of minerals to form scale. A boiler that receives only a small amount of new water can be expected to last for decades. Therefore, one way to assess the condition of a boiler is to find out how much new water has entered it.

Simply walking around a building looking for leaks is the most obvious way to prevent boiler damage. However, many leaks are not so easy to find.

For example, piping buried underground often leaks where nobody can see the leak. Steam heating systems in apartment buildings have "steam return pipes" running along on top of or below the basement floor to bring water back to the boiler. If these return lines are buried, they react with the soil and rust quickly, sometimes springing leaks when they are less than five years old. Return lines partly covered with dirt and cement are also vulnerable to shortened life. If return lines are exposed on top of the floor, they should stay that way. If the piping is buried it should be assumed to be leaking, and replaced with aboveground piping.

Steam heating systems can lose significant amounts of water from any one of many air valves throughout the system that can fail in the open position. Hot water heating systems lose water through valve packings and pump seals that leak water too slowly for the leak to be visible.

There are many clues available to help determine the amount of feedwater that has entered a boiler. Sometimes a foresighted person installs a water meter to measure feedwater. Periodic meter readings indicate how much water the boiler is losing. More importantly, an increase in readings reveals an increase in consumption and can alert people to look for the problem. Unfortunately, typical boiler installations do not include water meters and consumption history.

Examination of the boiler's pop safety valve or its discharge piping can reveal evidence of leaking at the valve. Rust or scaling on the discharge piping indicates water has probably been leaving the boiler through that piping. Many closed loop systems, such as hot water heating systems, have insufficient expansion tank capacity, which causes pressure to exceed the pop safety valve's pressure setting, which in turn causes the pop safety valve to do its job and discharge water. A new pop safety valve is a clue that the old valve probably discharged water regularly, and that the new one might do the same if the original problem is not solved.

Rust colored stains on the floor under the discharge piping are a sure sign of a boiler damaged by excessive feedwater. One trick I use is to push a business card into the discharge piping. If I am ever back in that same boiler room I can check to see if the card got wet since I was last there. Blow-downs and drains can be checked for drips and rusty stains, both of which are signs of discharging water. Some people do not like piping drains onto the floor, and insist on piping them directly into drain pipes, which can hide leaks. I saw one boiler in a 70-unit multifamily building on Broadway in Manhattan completely rotted out because someone left a drain valve partly open for months, but nobody noticed because the piping ran directly into the sewer.

Feed-valves usually have strainers that clog and need replacement or cleaning. A feed-valve or strainer that clogs or needs replacement more frequently than others in similar systems is a sign of excessive feedwater. If you see a few old water feeders or feed-valves lying around in the corner of the boiler room it is a sure sign the boiler is leaking. Another clue is rust on the surface of the feed-valve, which indicates a large quantity of feedwater is cooling the feed-valve enough to condense moisture out of the air and create rust on the surface of the feed-valve.

Other indications that a boiler has been serviced for leaks may be present. Used tube plugs lying around the boiler room usually indicate someone plugged a tube at one time, and the plugs were removed and left there for future use. Tube dimensions written in chalk on the wall indicate the person replacing tubes expects to be back. Obviously, discarded tubes or cast-iron sections in the boiler room are evidence of repairs to the boiler.

When one section of a cast-iron boiler is damaged enough to leak water or steam, people sometimes replace only that section. Unfortunately, all sections suffer damage from feedwater at about the same rate, so a good argument can be made for replacing all sections when one leaks. The same can also be said of a steel boiler.

The labor cost associated with replacing all sections is sometimes only a little more than the cost to replace one section because other sections usually need to be disassembled to remove the leaking section. In the real world, short-term thinking and lack of money often convince people to replace just the leaking section. When a steel boiler leaks, the leak usually is in a tube because the tubes are made of thinner steel than the rest of the boiler to increase heat transfer. When tubes leak they can be replaced or temporarily plugged. Usually when only one or two tubes leak it is reasonable to plug them to postpone the cost of replacement until later, when presumably a larger number of tubes can be replaced at one time.

While tubes are rusting and being replaced over the years, the rest of the boiler is also rusting, but damage to other parts of the boiler is not as noticeable because the thicker metal the rest of the boiler is made of takes longer to rust through. If enough oxygen enters the boiler, eventually the thicker parts get damaged enough to cause structural problems or leaks. Low-pressure boilers (with a maximum of 15 psig) typically are patched by welding new steel plates in place of damaged steel, but high-pressure boilers become unsafe once structurally damaged.

If a low-pressure steel boiler has had parts other than tubes repaired, such as shell or tube sheets, it is reasonable to assume the boiler is near the end of its life. Likewise, if a cast-iron boiler has had some sections replaced, it is reasonable to assume that the other sections will need to be replaced soon. In the case of a steel boiler, the boiler and its controls and burner generally get removed and replaced when the boiler gets replaced as economics and some codes prohibit the installation of used parts. In the case of cast-iron boilers, it is not uncommon to replace all sections of the boiler with identical replacements while keeping the controls, burner, and piping in place. This saves the time and cost of repiping and rewiring the boiler, and might save the cost of filing for permits if the job is considered a repair.

However, it is easy to overestimate the gain in fuel efficiency associated with replacing a boiler or burner. One common mistake is to compare the combustion efficiency of the existing, out-of-tune boiler to a new boiler that is presumably tuned perfectly. It would be more realistic to compare the efficiency of the existing boiler after a tune-up to the efficiency of the proposed new boiler. Much of the credit for efficiency gain commonly given to replacement boilers should be credited to the tune-up, new controls, and careful control adjustments done at the time the boiler is installed, all of which could be done to the existing boiler.

However, piping problems can be corrected without changing the boiler. Many people are quick to condemn a boiler because of problems associated with its operation and expect those problems to be eliminated by a new boiler. But that frequently means replacing equipment installed by someone who grew up building and fixing things with equipment installed by someone who grew up playing video games. Replacing a boiler is no guarantee that problems with piping or controls will get better. In fact, they may get worse.

Soon the room looks and smells so bad that people, including those who work on the boiler, want to spend as little time as possible in it. The owner's willingness to spend money on the boiler and the enthusiasm of the people who work on it are reduced, until eventually the boiler barely works and everyone involved advocates replacement.

A reasonable alternative to replacing the boiler is to buy new boiler doors and seal them up tightly, then clean the boiler room, and install additional lighting. The boiler would have a reasonable chance of working well for many years.

Cast-iron boilers have similar leak problems. Cleanout covers and flue gas collectors usually are attached to the boiler with special hardware that corrodes and is hard to use after repeated removal for maintenance and cleaning. If nobody takes the time to special order the hardware, cleanout covers leak, flue collectors warp and leak, and the boiler gets old before its time. Unfortunately, few boilers get treated to new doors or cleanout covers, and many boilers get replaced when the flue gas leaks get bad.

When contemplating whether to repair or replace a boiler, first assess the condition of the metal the boiler is made of, by whatever means are available. If the boiler is almost rusted through it should probably be changed soon. If the condition of the metal does not indicate near-term problems, a good next step is to estimate the cost of a new boiler vs. the cost of making enough improvements to the existing boiler to make it work about as well as a new one. Then a decision to keep or replace the boiler can be made.

30 Comments

Leave a Comment