The energy crisis of the 1970s created long lines of cars, with drivers waiting to fuel up at gas stations. These days, increasing fuel demands and rising prices are forcing the cost of everything from groceries to construction materials and other everyday expenditures ever upward. Heavy demand on the overtaxed utility grid has resulted in periodic blackouts in some major cities during summer months. Since utility costs comprise part of a building’s maintenance budget, maintenance costs for residential buildings also have been affected.

Same Problem, Different Approaches

These factors have forced the administrators of some cash-strapped buildings to take the unusual step of issuing special assessments to pay for spiraling utility costs. Boards and managers of other buildings are looking at their utility usage and thinking about how to lower—or even just freeze—their costs. More buildings are obtaining multi-year contracts for various services, but such deals are only short-term fixes for the long-term headache of exponentially rising costs.

While most co-op and condo buildings in the city get their energy from a major supplier like Con Edison (or from a secondary supplier), more buildings are choosing to generate some of their energy at their own facility, by implementing a co-generation program. A co-generating program produces a portion of the energy the building needs on-site. Sometimes in very large projects, a co-generation program can produce energy in excess of a building’s needs, enabling the building to sell some of the energy back to the utility company for a profit.

In most cases though, a co-generation program in a residential building will provide just a portion of the energy needed for running the building, and that energy will be used for the building. While instituting a co-generation program can result in a significant savings in utility costs for some residential buildings, co-generation is not for every building. Depending upon its size, the amount of energy it regularly uses, and its physical characteristics, adapting the building’s system for co-generation could make great sense. Or, implementing a co-generation plan might be downright foolish, and actually could cost the building’s residents more money.

Knowing whether your building is a good candidate for a co-generation system could save its residents money and years of hassle. Evaluating the potential of such a system for your building is not necessarily as tricky as it might seem. With the right professional counsel, a building’s management can make the right choice, either by co-generating or by sticking with the building’s existing system.

How It Works

Simply put, co-generation is the simultaneous production of two useful forms of energy from one process. For example, steam generated by a boiler could be captured and used to produce electricity or to provide for space heating in a building. In residential buildings, machines that can be used to co-generate generally run either on natural gas or #2 oil.

“Co-generation means you get two thermal products on one fuel; usually you get electricity and heat,” says Damian Sciano, project manager and engineering ombudsman for Con Edison. “It’s when you are already making electricity, and you use the heat—sometimes in the form of steam—from that process.”

No co-generation projects are entirely self-sustaining. Most co-gens will still take power from the municipal grid, at least during summer hours, but probably throughout the year, adds Sciano.

The obvious benefit of a co-generation system is that it uses previously untapped energy (such as heat) to provide for part of a structure’s utility needs. Providing the appropriate system is installed in a building, instituting co-generation should provide savings on utility bills over time. How long it takes for a co-gen system to pay for itself in utility savings depends largely on the system.

One potential feature of co-generation that can be especially attractive to those managing residential buildings is a system’s potential to work off the grid. Some co-generation units can be started independently, and be started in the event of an outage.

Co-generation might sound like a panacea for cities, but unfortunately, such systems aren’t appropriate for every building. A building’s size and utility usage are key factors in determining whether or not it could, or should, co-generate.

Adapting Your System

When a building’s management is considering co-generating, an advantageous time to do so would be when they are planning for a large mechanical replacement project. If the building is considering replacing its boilers, or its steam pipes, such a costly overhaul necessitates that all potential options be considered. In such a scenario, it might make a lot of sense to install a co-generation system.

In addition to cost, the question of utility usage also is paramount. A building’s load factor—the way it uses its electricity—is of particular importance. Determining the building’s average electrical use and dividing that figure by the building’s use during peak hours will determine its load factor.

“It helps if the building has a good load factor—that is, if the way it uses electricity is pretty constant,” Sciano says.

Other areas to examine when considering a co-gen facility in a residential building include whether there is space for the co-gen facility; if natural gas is available to power the facility; and whether the building has a central air conditioning system. A centralized air conditioning system generates heat, helping the load factor.

Depending upon the size of the co-gen system, one or more employees may be needed to maintain the facility, sometimes around the clock. Having enough space for the unit also can be tricky, especially in New York. A co-gen facility for a 100-unit residential building would need about 20 feet by 20 feet of space.

For Penn South, a multi-building co-op community in Manhattan’s Chelsea neighborhood, planned capital improvements 22 years ago led management to consider switching over to a co-generation system. The community had a steam pipe system at the time, and antiquated boilers—all of which needed to be replaced.

“We thought if we could get rid of the boilers and use the byproduct to heat the hot water system, there could be significant savings,” says Brendan Keany, general manager of Penn South.

Mike Gordon, chief strategy officer for ConsumerPowerline in Manhattan, recommends that residential buildings with a facility that creates a lot of heat at least consider co-generation. “Anyone with a pool should do it, because you can use that heat effectively,” Gordon says. “New York City intends to achieve reduction in energy consumption over the next eight years. Co-generation is often classified as renewable. It reduces the carbon footprint.”

Sciano cautions that a building’s management should take particular care in determining its load factor before installing a co-generation system. cent of the time.”

Part of PlaNYC

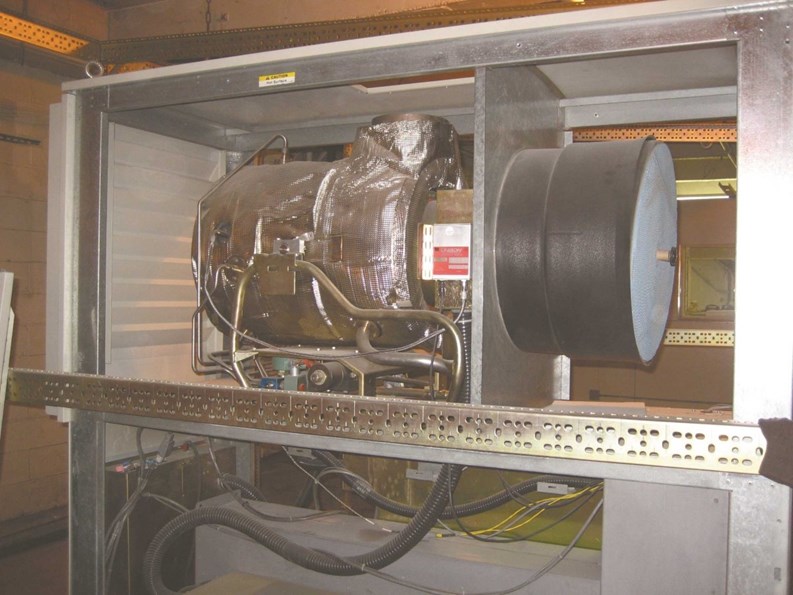

One of the co-generation options these days is installing a microturbine system. This equipment which is about the size of a soda machine can be put almost anywhere mechanical equipment goes, like inside a boiler room, the basement or on the rooftop of a building, according to Bruce Beckwith of RSP Systems in Brooklyn.

Using this type of equipment is actually one of the mandates of Mayor Michael R. Bloomberg’s PlaNYC 2030 master plan for New York City. Late last year, Bloomberg announced a rule setting a standard for city buildings to reduce harmful emissions. “This rule will help us to meet our commitment to reduce greenhouse gas emissions citywide by 30 percent between now and 2030, and it will help spur the real estate and development communities to build more efficient, greener projects moving forward,” Bloomberg said in a statement.

Buildings in New York City generate 79 percent of the city’s greenhouse gas emissions. By supplying on-site power generation to buildings, microturbine systems provide an energy-efficient supplement to power plants, New York City’s conventional power supply. Estimates show, for a given amount of fossil fuel, microturbines generate 70 to 80 percent of its usable energy, whereas only 30 to 35 percent of the energy produced by power plants is usable.

Here’s how it works. Natural gas goes into the turbine to produce electricity and thermal energy. “Simply put, with co-generation you have two types of energy going out with one type of energy going in,” explains Beckwith. “We’re taking natural gas in. We’re making electricity and reclaiming wasted heat and turning it into hot water. We’re displacing electric demand and usage and also displacing traditional boiler use.” It could also work in conjunction with an HVAC system to provide chilled water for air conditioning as well.

A building using co-gen could operate entirely off the grid and be self-sufficient. Additionally, some of the reclaimed energy can also be put back onto the power grid helping the city prevent blackouts or brownouts.

This system could be installed in a new construction, as it was in the Millennium Towers Residences in Battery Park City, or can be retrofitted to work with the existing energy systems in a building, he says. One of the benefits of a microturbine, unlike a traditional boiler, is that it has few moving parts. It basically runs on compressed air and doesn’t need any oil or lubricants.

The system installed at the Millennium Tower Residences is a 60kW unit to provide domestic hot water to the top half of the 234-unit apartment building. The Millennium Tower Residences is the first LEED Gold-certified condominium in BPC. According to Charles Norman, project manager in design and construction for the property, the microturbine generates about 10 percent of the electrical load needed to power common areas, and heat about half of the building’s hot water. The installation cost for the equipment was roughly $250,000.

Other current installations, Beckwith says, are in a new building on Fox Street in the Bronx, where a microturbine is providing domestic hot water and water for heating the building, and a Park Avenue building, which is seeking a system for backup generation.

The city’s rule allows for microturbine systems to be installed in residential or commercial buildings provided clearance is obtained from the utility company and an application is filed with the Department of Buildings. An operational permit from the FDNY is also necessary. While cost is hard to define, most buildings will see a three- to four-year return-on-investment, according to Beckwith, with a typical service and maintenance agreement of about nine years.

Benefits & Drawbacks

In addition to the upfront cost of buying and installing a co-generation system, providing funds to pay for new employees to maintain the system may be beyond a building’s means. The cost to install a co-generation system in a residential building usually starts at around $1,500 per kilowatt. Conversion of a 100-unit building to co-generation could cost from $150,000 to $300,000, Sciano says.

Installation costs don’t account for the ongoing costs of salaries for workers to maintain the co-generation facility, however. While smaller facilities might need the care of one or a few people, a large structure will require a more significant staffing commitment. Keany says that Penn South had its system updated a dozen years ago, and the 2,820-unit community has a boiler room staff of 14 people.

That said, management at Penn South determined two years ago that the system was saving about $500,000 per year in utility costs, and Keany estimates that it now saves about $700,000 annually. Though, a building should probably have at least a couple hundred units for a change to a co-generation system to make sense, especially right now. Fuel prices and technology are uncertain and changing rapidly, and moving to a co-generation system could be unadvisable.

“If I were a co-op board, I would wait a few years to co-generate,” Keany says, adding that fossil fuel use and prices are still in flux. “Hopefully, technology will catch up, because costs are so high.”

The question of “future-proofing” technologies also is important to mull, Keany says. “The concept of future proofing [includes asking the question:] does it make sense to make the change now, or would it make more sense to wait for some other technology, such as solar panels, which might make more sense in the [near] future,” Keany says.

More Buildings Co-generating

While more buildings are making the change, the trend is fairly limited, Sciano says. Currently in New York there are about 100 “active” co-generation projects. “Active” means the projects at least have paperwork filed with the city regarding the work. Much more is entailed in the process of changing over to co-generation, which is partly why far fewer buildings install the systems.

“The projects that get done [each year] are in the dozens,” Sciano says. Whether more buildings choose to follow suit and explore the possibility of co-generation remains to be seen. But, with fuel costs continuing to rise and New York City’s push toward a greener more sustainable environment, it seems likely that other buildings will at least look toward co-gen as one possible option for cutting costs and saving residents money in the long run.

Jonathan Barnes is a freelance writer and frequent contributor to The Cooperator and other publications.

Leave a Comment