On July 1st, about 10,000 New York City buildings must start phasing out their use of high-polluting fuel oil. Under the city's “Clean Heat” mandate (a part of Mayor Michael R. Bloomberg’s Greener, Greater Buildings Plan New York initiative), permits are being phased out for No. 4 and No. 6 grade heating oils. Permits required for using No. 6 oil—the worst polluter of the three main types of heating oil—were discontinued in 2012 and permits for No. 4 will be denied beginning this summer, as boilers and burners are replaced to comply with the new law.

Since the majority of emissions and thus the bulk of the city’s carbon footprint are created by buildings that often have outdated and inefficient heating systems, bringing buildings into compliance with the Clean Heat regulations ultimately will create a less wasteful Big Apple with clearer skies. There is another silver lining to this regulatory cloud: the savings that can be achieved by multi-family buildings through transition to a more efficient boiler, or even from heating oil to natural gas-powered heating systems, can be significant and long-term. This potential for savings makes a methodical approach to compliance with the new law all the more important.

Starting to comply with the new law means doing your homework and often, also having a mentor in the process. Considering the pros and cons of a system alteration, replacement or upgrade to a gas-powered system shouldn’t be just the concern of residents, board members and property managers—often, an expert should be hired to manage the process. But not always; sometimes a simple upgrade of a decent system to No. 2 oil is all a building’s residents need and want. Evaluating the heating/cooling system and boiler, as well as its components, is just the start of the process.

Why Phase Out?

There are a variety of reasons for the phase-out. It’s partly about saving money and natural resources, but primarily the new law is meant to help clean up a city which has pollution that is known to adversely affect children and others who can’t afford it, like the elderly. Creating a cleaner and greener New York City, from the perspective of the mayor, is another way that the city is protecting the health and interests of the citizens. It’s also good for business: having clean air and efficient heating systems (and because of that, lower residential building maintenance fees), and perhaps even fewer cancer clusters due to less pollution, are always good characteristics for a city’s “livability” rating.

Studies have shown a strong correlation between lung diseases and burning No. 6 oil, says Frank Lauricella, director of business development for The Daylight Savings Company, an energy efficiency consultant/engineering firm in Goshen. The recognition of the connection between lung-related diseases like asthma and No. 6 fuel oil led to the change, he says.

In this busiest city in the world, people want it all. They expect the convenience and luxury and the access but they don’t want the concomitant waste, filth and stink that seem to accompany progress wherever it is happening. The Clean Heat law satisfies many of these needs, allowing residents to live a bit more comfortably and healthily knowing that their family, friends and co-workers will be breathing easier because of cleaner air resulting from well-planned capital improvements to their buildings.

For many people all oil might seem the same, but the differences between the grades of oil can be stark. The grades of the three heating oils are based on how much each has been refined. Because No. 6 is the least refined and the lowest quality, it has the most toxins. It is thick and sludgy and must be heated first to be used for a boiler. An electric heater apparatus on the side of the boiler that is used to heat No. 6 oil is constantly running, and constantly burning energy.

In the mid-range is No. 4 oil, which is a blend of No. 2 oil and No. 6 oil. Of the three types, No. 2 oil is the most refined and is close in quality to diesel fuel. It also is the most expensive of the three.

“Number six oil is being phased out because it’s filthy and full of pollutants like heavy metal,” says David Kuperberg, CEO of Cooper Square Realty, the largest residential property management company in New York City. “Emissions from the other oils have less sulfur dioxide. Number two oil is more highly refined to eliminate harmful chemicals.”

Where the switch from heating oil to natural gas is available, it makes sense for many buildings to make the change, experts agree. The price of natural gas is more economical compared to heating oil for a building’s boiler, and that differential should continue for a long time, industry insiders say.

Retrofits and Replacements

If those with the right knowledge are guiding you, the process of upgrading or retrofitting a boiler to be compliant with the Clean Heat policy needn’t be tough. Changing from No. 6 oil to No. 2 oil, or from an oil-consuming system to a gas-consuming system, is a lot smoother when residents understand their options. Those options can be explained by a professional such as an engineer who is conversant in the oil changeover, an energy efficiency expert, or a qualified boiler maintenance company.

Residents who want to educate themselves on the matter can do so by attending seminars on the changeover. Whether or not they have such firsthand knowledge, all board members should seek the help of an expert to do a feasibility study before any work is done on changing the heating system, Lauricella says. “You need to know the direction you’re going is the way to go,” he says.

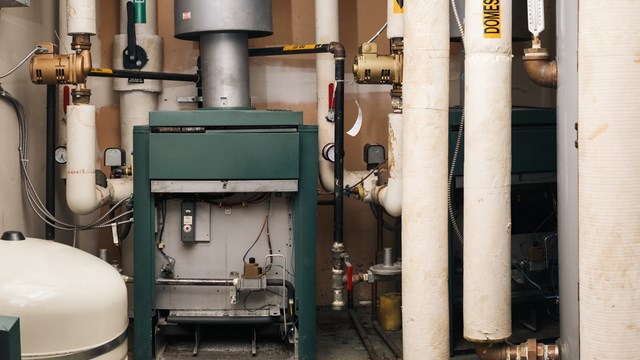

A feasibility study will examine the limitations and usable life of the building’s heating system. This preliminary inspection of the system and its layout will help determine if changes to the boiler or to the boiler room (such as removal of or erection of walls) will be needed. The study also will determine if the system can burn No. 2 oil and if so if that is the best course of action, or if a changeover to natural gas is the best option, or not an option.

After a board decides upon the modification or boiler replacement plan, the engineer should create specifications for the work and put out a request for proposals for the project. After receiving RFPs from contractors interested in the work, board members can choose the best contractor for the job.

Based upon where they are located, some buildings will have a tougher time in trying to convert to natural gas, because utility companies are loathe to install new distribution lines to the buildings unless they see a great need. In some parts of the city, there is no natural gas line to service such needs, or the line that exists can’t provide the supply of gas needed to heat the building.

What's involved with switching oil types or converting to natural gas, in terms of actual boiler machinery depends, of course, upon the state of the building’s boiler. The age of the boiler may dictate that it be replaced, and whether or not it can be adapted to run on the cleaner oil or natural gas also is a consideration. The costs for a retrofit, versus the cost of a replacement of the boiler, are other factors that will need to be assessed.

Many existing boilers can be easily retrofitted to use the new oil. But some are just too old and inefficient and should be replaced anyway, so it makes no sense to retrofit them when a replacement will save you money sooner and later.

“Boilers are like family members, you should prepare for their demise,” says Andy Padian, vice president, energy initiatives, for New York City-based Community Preservation Corporation (CPC), an affordable housing lender. “So when boilers die, by code, they die on Christmas Eve… There are co-ops with boilers at death’s door, and they haven’t maintained the boiler or even removed friable asbestos around it.”

“Friable” asbestos is old and dry, uncontained toast-like pieces of the once commonly used insulating material, microscopic fibers of which become airborne and can cause lung scarring and mesothelioma when inhaled.

Roughly speaking, a board might expect to pay thousands of dollars to hundreds of thousands to get the building compliant with the new standards. Obviously, if a boiler is in good shape and already is equipped to handle No. 6 oil and No. 2 oil, not much needs to be done to become compliant. Residents can ascertain this with the help of a professional, who can inspect the system and tell whether the boiler’s burner apparatus can burn a different grade of oil.

A really old inefficient boiler or group of boilers, though, might need to be completely replaced in a costly project. At the same time, asbestos removal work might also need to be done, upping the cost. Other scenarios that could impact the cost of retrofitting or replacing a boiler include the need to reconfigure spaces, and in the case of changeovers to natural gas-fed systems, the condition and lining (or lack of lining) of the chimney or the need to pay for a new line to feed gas into the building.

Safer Numbers

“This law is forcing buildings to do what is economically good for them and good for the environment,” Kuperberg says. “Gas is so much cheaper, that if it is available [for conversion of the heating system], the paybacks on the conversion can be two to five years, and a twenty to fifty percent return on your money.”

Whatever the decision chosen for the building, being able to convert the heating system over to natural gas or back to oil is essential, Padian says. World events could change the cost of oil or natural gas, so being able to convert back to one or the other is really just being prepared.

By banding together, some residential buildings have been able to get Con Ed to install much-desired natural gas lines in their areas. Clustering—the grouping together of a few or more buildings that want gas lines installed—has been a successful method of achieving this change, Kuperberg says.

“The market is dictating this but people are reluctant to change,” Kuperberg says. “I thought the change would happen through economics alone, but a law was necessary.”

Paul T. Brensilber, president of New York-based property manager Jordan Cooper & Associates, says the Clean Heat program is a no-brainer. “If Con Ed could handle the distribution, everyone would change to gas and contractors would be doing all that work… We’re waiting right now to find out about the gas distribution line loads for five buildings,” he says.

It’s tough to find professionals in the industry who are against the new mandate, Brensilber says. “There is no other capital improvement that will give you a better return on your investment than boiler conversion,” he says.

Jonathan Barnes is a freelance writer and a frequent contributor to The Cooperator.

Comments

Leave a Comment