With the economy moving back toward a more robust state, building administrators are still looking for ways to save money in an increasingly competitive real estate market. It’s no surprise to hear that co-op and condo boards sometimes feel compelled to prioritize (or deprioritize) certain maintenance and repair projects over other projects—it just makes sense to do so when times are more conservative.

While it's clear that installing a new boiler or roof should take precedence over a lobby refurbishing project, sometimes, the right course isn't clear-cut. Some reshuffling of priorities may be unavoidable when money is tight, but the process also raises some questions about liability, long-term planning, and how boards and managers can make wise decisions in tough times.

Must Do’s

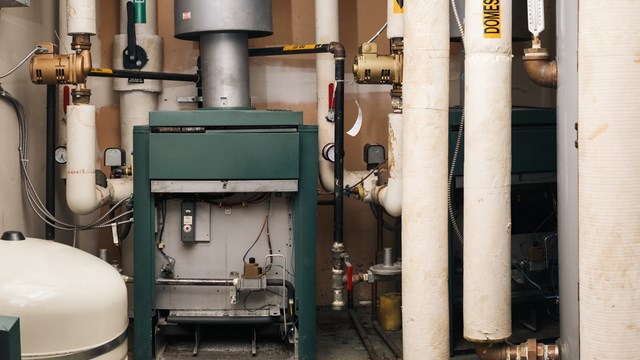

Certain routine maintenance projects absolutely cannot be skipped, including regularly checking the state of the building’s roof to take note of and address normal wear and tear; also, checking the roof drains, even in winter, when a clog up there could quickly prove disastrous. The building’s boiler requires a regular schedule for checkups by boiler maintenance professionals, as well as--at least--weekly checks by building staff, who should be monitoring how the device is running and noting it in a logbook.

A building’s boilers, HVAC system and water tank all must be checked and serviced, at least, yearly. The sprinkler system, alarm system and the elevator system also must be addressed annually, says Stephen Beer, managing director of Manhattan-based accounting firm Czarnowski & Beer.

There are obvious signs of an impending maintenance crisis that boards and managers should never put off addressing, including when residents report smelling gas, or when the heat doesn’t work properly, or if the boiler has been having a lot of similar repairs done repeatedly.

Some maintenance is mandated by the building code, including the Facade Inspection Safety Program (FISP), formerly called Local Law 11, which requires scrutinizing the building’s exterior every five years to ensure there are no hazardous conditions, such as loose pieces of the façade that could fall off and hurt someone. Also, city law requires annual cleaning and chlorinating of the building’s water tanks.

Annual elevator inspections also are required by law, and must be performed by a consultant specializing in elevator maintenance and repair. Such a checkup will involve looking at the entire system, including the controllers, motor, gears and the machine itself. This work needs to be witnessed by a qualified third party to ensure that it is done properly,” says Doug Weinstein, director of operations for AKAM Associates, a New York-based management company.

The annual inspection of the boiler system needs to be performed by someone with an oil burner installer’s license, and should include cleaning the boiler and burners. HVAC systems should have routine maintenance done when the system is shut down at the end of the cooling season. The building’s fire suppression system must be inspected monthly by a professional with a certificate of fitness (which is typically held by the building manager or superintendent). A test should be done at least every five years on the sprinkler and standpipe system. Fire department officials should monitor this test; typically, they do so after a pre-test is done by professionals to ensure the system will pass muster with fire officials.

Also, a yearly inspection and test of the building’s backflow preventer must be done. This device is attached to the building’s main water supply line, and prevents water from going back out of the building and flowing into the city’s main water supply. Other aspects of the building’s infrastructure must be vigilantly watched, too.

“You’re constantly doing visual inspections of the roofing system, year-round. A lot of times, what will happen is that damage will be caused to coping stones and to brickwork on the parapet walls,” Weinstein says.

Vigilance is essential when it comes to avoiding unnecessary, costly repairs. Any qualified building professional, like a superintendent or property manager, should be able to spot problem areas such as roof leaks, basement foundation leaks, or compromises in the boiler’s functioning.

“On an ongoing basis, you have to be looking for areas where moisture is getting in,” says Mitchell Frumkin, PE, RS, CGP, president of Kipcon Engineering, which has offices in New York and New Jersey. “It’s easy to see damage on your roof to the seams and flashing— probably one of the most important building systems is the roof—which should be checked in the fall and after winter. Every piece of mechanical equipment on a building should be checked on a regular basis.”

Have a Plan

Some projects or maintenance items can be spaced out a little more to save money, like a refurbishing project on a lobby that was remodeled just a decade ago, or a façade improvement that isn’t necessary for safety but is meant to improve the appearance of the building. While they may be helpful to sales, such projects are not essential to property management. Also, repaving an asphalt parking lot that has just begun to show signs of wear may not be essential; it could make more sense to consult the paving company and ask if the lot can be patched and repaired to give it more life, before having to totally replace it.

Similarly, repainting the hallways and replacing carpet there might not be immediately necessary, if those areas still look presentable and not downright shabby. A total replacement of windows in the building might simply be an energy efficiency enhancing project, also, but not really crucial. Since such a job can cost a bundle, sometimes, it could make sense to space out the window replacement in phases over years, to spread out the cost.

In many cases, waiting to do an improvement or maintenance job simply isn’t wise in the long run. When the management puts off certain tasks, they run the risk of things costing more to fix or upgrade, or of incurring other costs associated with delaying the work. Think of a small leak in the roof; it will not get better and will surely get worse, sometimes much worse, very fast. A small drip could quickly turn into a virtual downpour for residents living on the top floor.

“You never want to ignore any sort of water infiltration because it could lead to more expensive repairs down the road and a machine of any sort will make a certain noise when working properly. If that noise changes, that usually means there’s something that needs looking into,” Weinstein says, noting that residents smelling gas is a prompt to take more preventative measures. “We recommend that buildings have a hand-held portable gas detector on hand.”

It has been said that a boiler is bound to break down on the coldest day of the year, and there is some truth to the assertion, given that a boiler is most stressed when it has to work the hardest. The harshness of the just-passed winter is a good example of why boiler maintenance should never be put off.

“If you don’t keep up with the boiler system, it will conk out on a very cold day like today, when it’s the most inopportune and when repairmen are hardest to get,” he says, speaking of the icy cold days of February.

Between boiler checkups, a building’s staff can evaluate the machine’s efficiency by having professionals attach monitoring equipment to the boiler and remotely view its readings. Often, this will uncover problems in the system that becomes evident due to irregularities.

“If energy use by the boiler spikes, a lot of time it’s because maintenance needs done—like a clogged boiler filter,” Frumkin says.

There can be legal and liability ramifications of a board or management team choosing to wait on performing maintenance on a building feature or piece of equipment, if that feature or equipment fails and inconveniences residents or interrupts service to them. In the freezing cold of a winter like the last one, lack of heat in a building could harm property, or worse—it could harm people and their pets. Board members are tasked with ensuring that such an emergency doesn’t happen.

“The board members have a fiduciary responsibility to maintain the building…if they run the boiler when it’s not functioning properly and it breaks, residents could sue the board for damages,” Beer says.

The management team should seek professional input when making decisions about how to prioritize their building’s maintenance needs and schedule. Ideally, a board will know where and when to spend the money needed for maintenance and will plan for that spending years ahead of time. A building doesn’t need a lot of money to do such planning; its board just needs to have the right professional help, and to be prepared with the right questions for those consultants. Having well-qualified property managers, superintendents, engineers, accountants, and other consultants are important to maintain the property well.

Many property management companies will insist that their buildings have a maintenance plan. Some building boards hire engineers to develop ongoing maintenance plans, which often are 5-year plans. That way, the management team schedule for upgrades which will be needed, such as replacement of a boiler or roof that’s near the end of its usable life. Some buildings also have engineers do reserve studies to monitor each of the building components’ useful lives.

“A lot of times people don’t realize that spending a little money in the short-term will save you a lot in the long-term,” Frumkin says.

The management team should seek advice from its professionals to determine their maintenance needs. In coming up with questions, the team should first consider the importance of the building system. (It’s never an option to allow a boiler or HVAC system to break down, for example.) Also, the comfortable living of the residents must be considered when planning repairs, as should the cost involved in the repair, and the time of year it is (and whether or not the repair needs to be done at that time),” Beer says.

AKAM specializes in developing maintenance plans for buildings. To create such a plan, the firm goes into a building and assesses the types of mechanical systems it has and their state, and then develops a preventative maintenance plan to address those needs. Industry experts contend it’s the prudent thing to do.

“If you don’t do maintenance on a system and something happens and there’s damage, coverage could be denied. The insurance company could deny the claim for failure to maintain,” Weinstein says.

Such a failure of one of the building’s systems could wind up costing residents a lot of money out of pocket, when the problem could have been prevented in the first place through regular maintenance. Projects that haven’t been planned for—like a major roof repair or an emergency replacement of the boiler—can require immediate funds, in order to be completed.

“We’ve seen a lot of buildings where there was no maintenance plan, and funds needed to be raised through assessment. Planning is a key aspect to a lot of building management,” Weinstein says.

Jonathan Barnes is a freelance writer and frequent contributor to The Cooperator.

Leave a Comment